Ultrasonic Drivers / Generators

Introduction to Driving Ultrasonic Actuators

Bolt-clamped Langevin transducer with two piezoelectric layers (www.mmech.com)

Applications of ultrasonic technology can be broadly grouped into two categories: sensing, and actuation. The topic of this tutorial is actuation applications which require the continuous, or semi-continuous generation of high-power ultrasonic vibration. Applications include:

- Medical devices such as scalpels and dental tools

- Machining, drilling, and cutting tools

- Welding for plastics and metals

- Ultrasonic cleaning

- Sonication for fluid mixing and chemical reactions

The most common type of ultrasonic actuator is the bolt-clamped Langevin transducer, pictured left. These actuators consist of piezoelectric discs sandwiched between metal electrodes. The center bolt preloads the structure with a compressive force that is sufficient to prevent tensile forces during operation. The threaded centre hole is also used to mount the transducer onto a load, or concentrating horn. Continue reading full tutorial…

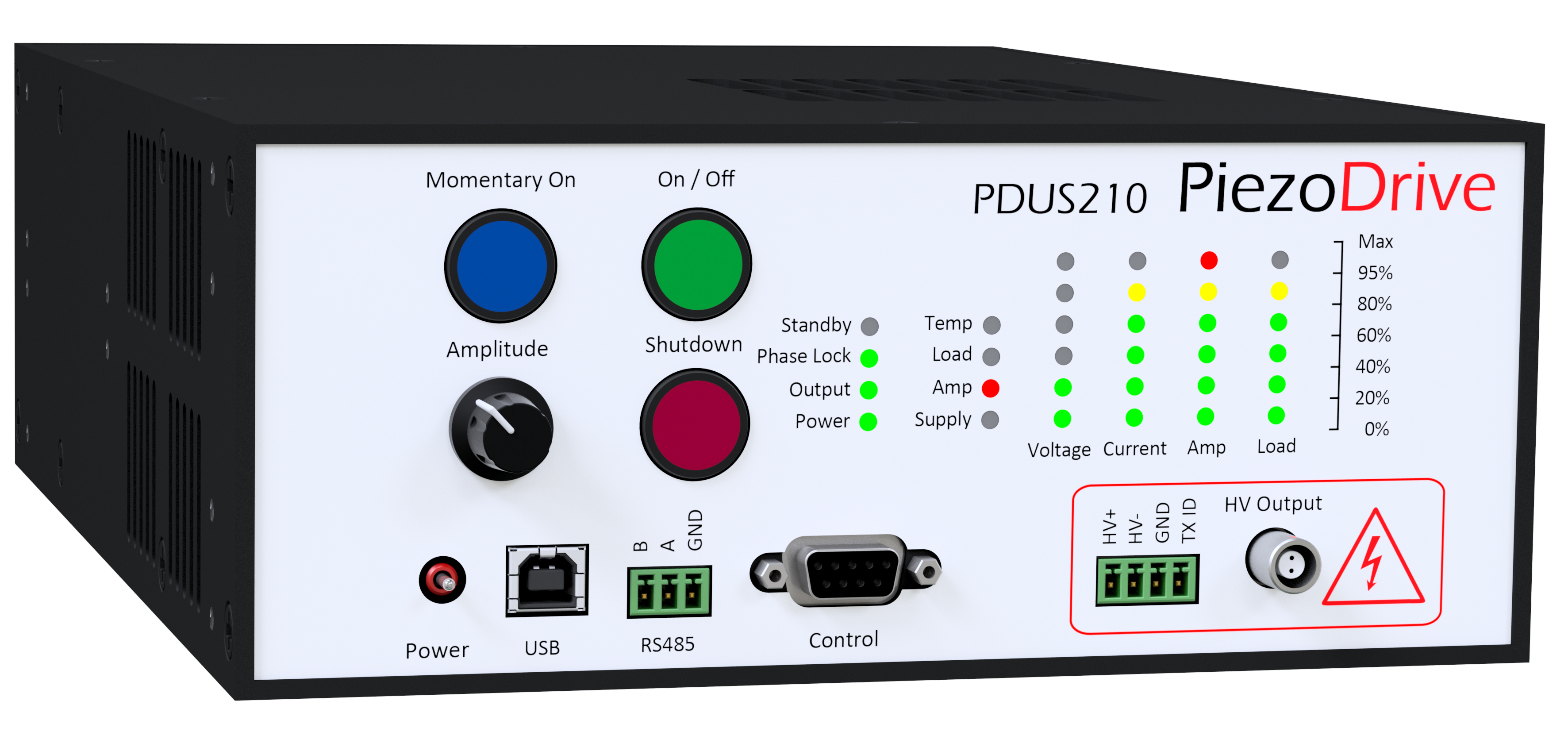

PDUS210 - 210W Ultrasonic Driver and Analyzer

The PDUS210 is a complete solution for driving precision and high-power ultrasonic actuators. The amplifier includes high-speed resonance and anti-resonance tracking, power control, and functions such as impedance and frequency response analysis. The PDUS210 is well suited to both OEM product integration and laboratory use for research and development. Applications include ultrasonic drilling and cutting, medical devices, dental devices, ultrasonic testing, liquid cavitation, and vaporization.

Key features include:

- Output voltage range 0 – 800 Vp-p (Customizable)

- Peak output current 0 – 32 Ap-p

- Frequency range 20 – 200 kHz (5 kHz to 500 kHz possible)

- Precision resonance and power tracking

- Built in frequency response analysis

- USB Control and monitoring

- Programming interface via RS485

- Comprehensive overload protection with shutdown